Plate Type Heat Exchanger Gaskets

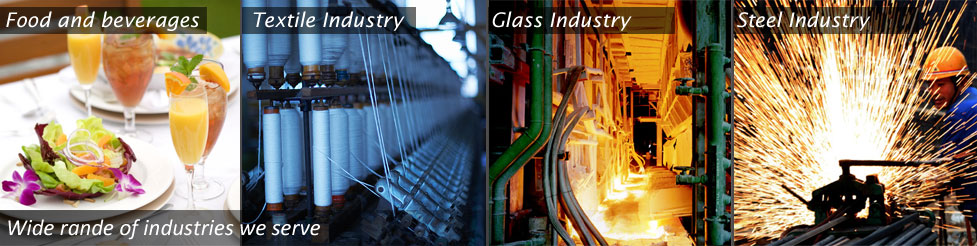

Accurate Rubber Industries is leading high quality Industrial Rubber Gaskets, Plate Type Heat Exchanger Rubber Gaskets Manufacturers & Suppliers in Mumbai (India). A Plate Heat Exchanger consists of a number of pressed & punched gasketed channel plates. These are clamped together in a frame by tightening bolts. Alternate plates are inverted and the gaps between the plates form liquid flow channels, each liquid flowing in alternate channels. The liquid is sealed against the atmosphere by RUBBER GASKETS. Therefore not only the plates but also the gaskets have very important role to play for the effective operation of the equipment.

The right selection of material (MOC) for required working Parameters and its correct designed configu- -ration plays a vital role for smooth and successful running of PHE. While selecting the suitable material (MOC) for rubber gasket for required parameters, we normally choose it out of polymers like :

- NBR (Nitro Butadine Rubber)

- Neoprene (Chloroprene)

- EPDM (Ethylene Propelene Dien Monomer )

- Butyle - Resin cured Butyle Rubber, Chloro Butyle, Bromo Butyle

- Viton - (Floro Elastomer)

- Silicone

- Hypalon

Physical properties:

We make Rubber Gaskets for temperature resistant from -72 dg.C to high temp. Resistant for 110 dg. C, 125 dg. C, 148 dg. C, 200 dg.C, 250 dg. C, 315 dg. C, Minimum Compression se and permanent set, Resistant to Gas, Sea Water, Oil (Edible and Non-Edible) steam etc. resistant to impact shocks, vibration, Radiation, Corona - Ozone, Infrared, Ultra Voilet Rays.

Chemical properties:

We manufacture rubber Gaskets to withstand/resistant destructive effect of most of the organic & inorganic fluids.

Rubber Gasket for any type and make for plate heat exchanger not shown herein can be developed & manufactured by us within a specific period. Our plate heat exchanger gaskets manufacturing range varies from 200 mm. to 3000 mm. length i.e. smallest to biggest.

Product Gallery :